Whitepaper

Crystallization in the Pharmaceutical Process

November 2022

- Biopharma

- Bioreactors

- Data-Logging

- Parallel Reactions

- Reactors

Crystallization is explored through its four main types—cooling, anti-solvent, reactive, and pH-controlled—along with examples and key applications. The role of impurities, seeding strategies, and process control are emphasized, as well as the importance of PAT, DoE, and QbD in optimizing outcomes. Scale-up considerations and the value of crystal structure analysis and modeling are also highlighted.

Interested in the Content?

Please fill in this form to receive your download link by mail:

Used Products

Reactor-Ready Filter Lab Reactor

Reaction and filtration in a single jacketed vessel setup, ideal for crystallisation, reaction workups, and product isolation.

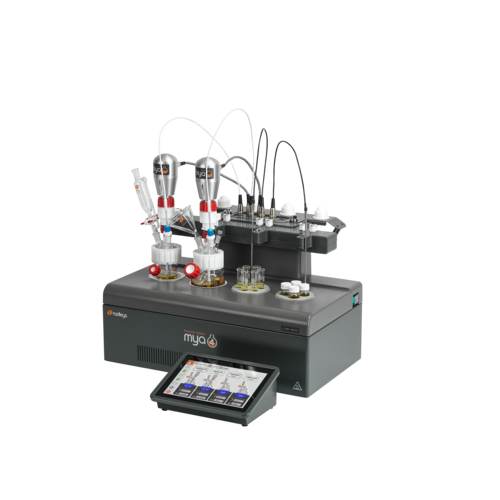

Mya 4 Reaction Station Kit

A flexible discovery tool for single or parallel synthesis, lead or reaction optimization, reagent, catalyst, and solvent screening.