Case Study

Efficient high-purity distillation of botanical extracts

August 2025

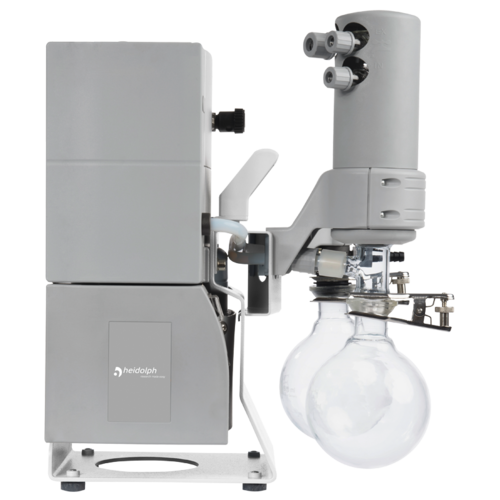

- Hei-VAP Industrial

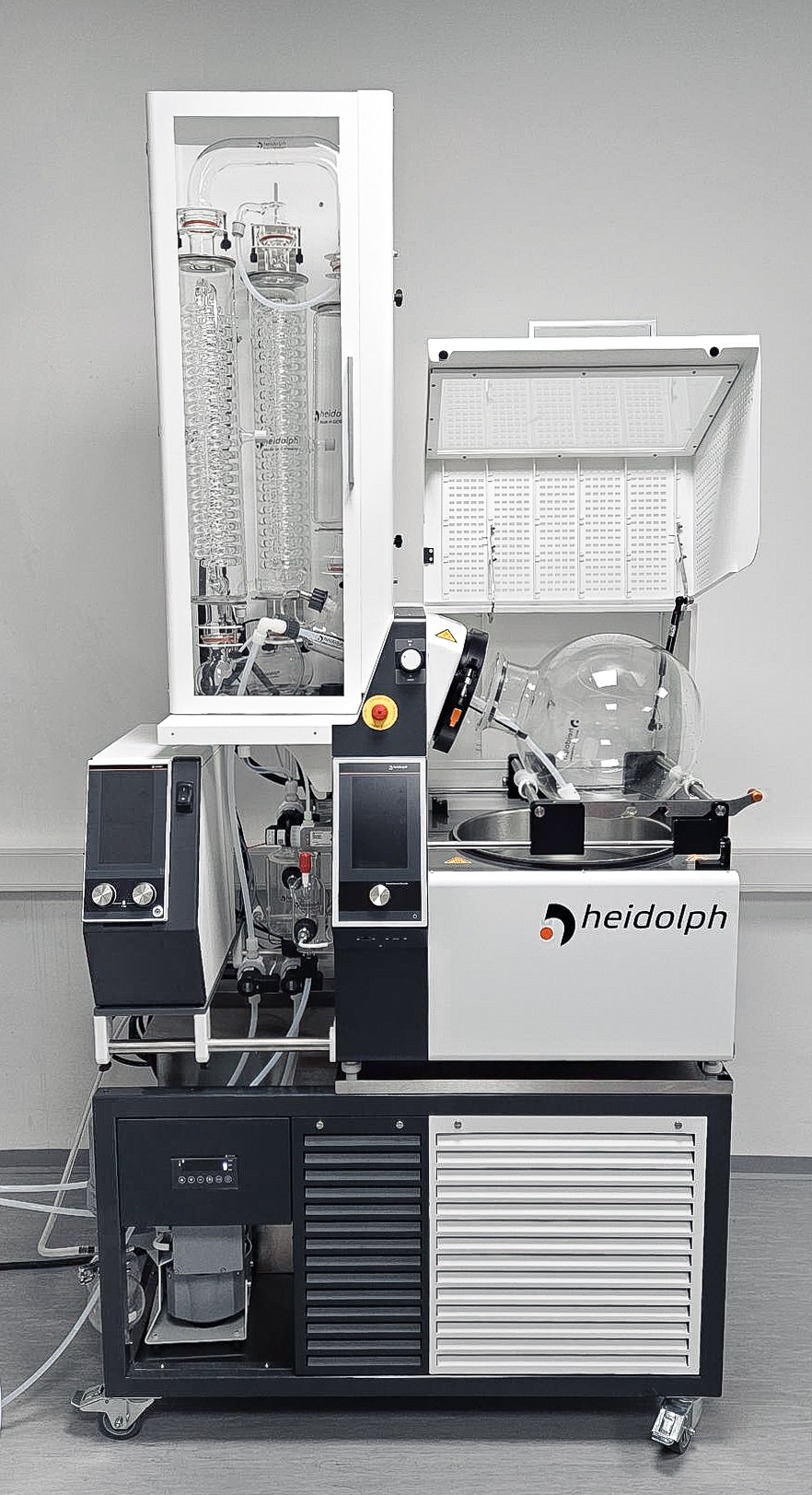

- Hei-VOLUME

- Automation

- Distillation

- Evaporation

Customer: Bootleggers (Austria)

Industry: Botanical Extracts / Aromatics / Spirits

Application: High-purity distillates from oil- and sugar-rich macerates

Background:

Bootleggers specializes in the production of botanical extracts and distillates. The process typically involves macerating plant-based materials in ethanol, followed by solvent recovery through evaporation. A key objective is to reclaim ethanol efficiently, even from challenging feedstocks that may contain high levels of oils, resins, and sugars.

Challenge:

The company regularly processes large volumes of feed material—up to 5000 liters—which are stored in tanks located several meters below the evaporation unit, requiring to overcome a 4-meter height difference. The macerates often contain either:

- High sugar (fructose) content, which can crystallize or caramelize during evaporation, or

- High concentrations of oils and resins, which tend to adhere to system components, reducing efficiency and increasing cleaning requirements.

Solution:

Bootleggers uses the Hei-VOLUME Distimatic Pro Industrial setup in time mode, allowing for careful process control and adaptation to different feedstocks. To manage the variability in composition, the team applies tailored strategies:

- Sugar-heavy extracts are diluted to facilitate easier removal of sugars in the residue stream.

- Resin- and oil-rich extracts are handled by lowering solvent efficiency, intentionally leaving more ethanol in the evaporation flask to flush hoses and system components, reducing residue buildup.

Evaporation parameters are adjusted based on the desired outcome:

- Low pressure operation with low temperatures (35–38 °C) is used for heat-sensitive or volatile compounds.

- Higher pressures with higher temperatures are used when higher throughput is prioritized and thermal sensitivity is lower.

Results and Performance:

- Typical feedstock: ethanol-based macerates with 80% alcohol by volume

- Output distillate: 92–95% alcohol by volume, indicating high ethanol recovery rates

- Yield: Over 98%, even with challenging resin loads

- Throughput: ~6 liters per hour under optimal conditions for heat-sensitive or volatile compounds

Conclusion:

Bootleggers has successfully adapted its evaporation process to meet the demands of high-residue botanical extractions. With time-controlled distillation, intelligent dilution strategies, and flexible pressure and temperature control, the company ensures large-scale production of high-purity botanical distillates and extracts.

Customer feedback:

“We are very satisfied with the system, as it has exceeded the purpose for which it was actually purchased after a short time. It is now being used in far more production setups than planned and has created the need for another development setup in just a few months. To summarise: It does what it is supposed to do - in the best sense of the word.”

Andreas Dolezal-Wurbs, Strategy & Product Development

Used Products

Hei-VOLUME Distimatic Pro Industrial