Case Study

Automated Solvent Purification for High-Purity Polymer Production

August 2025

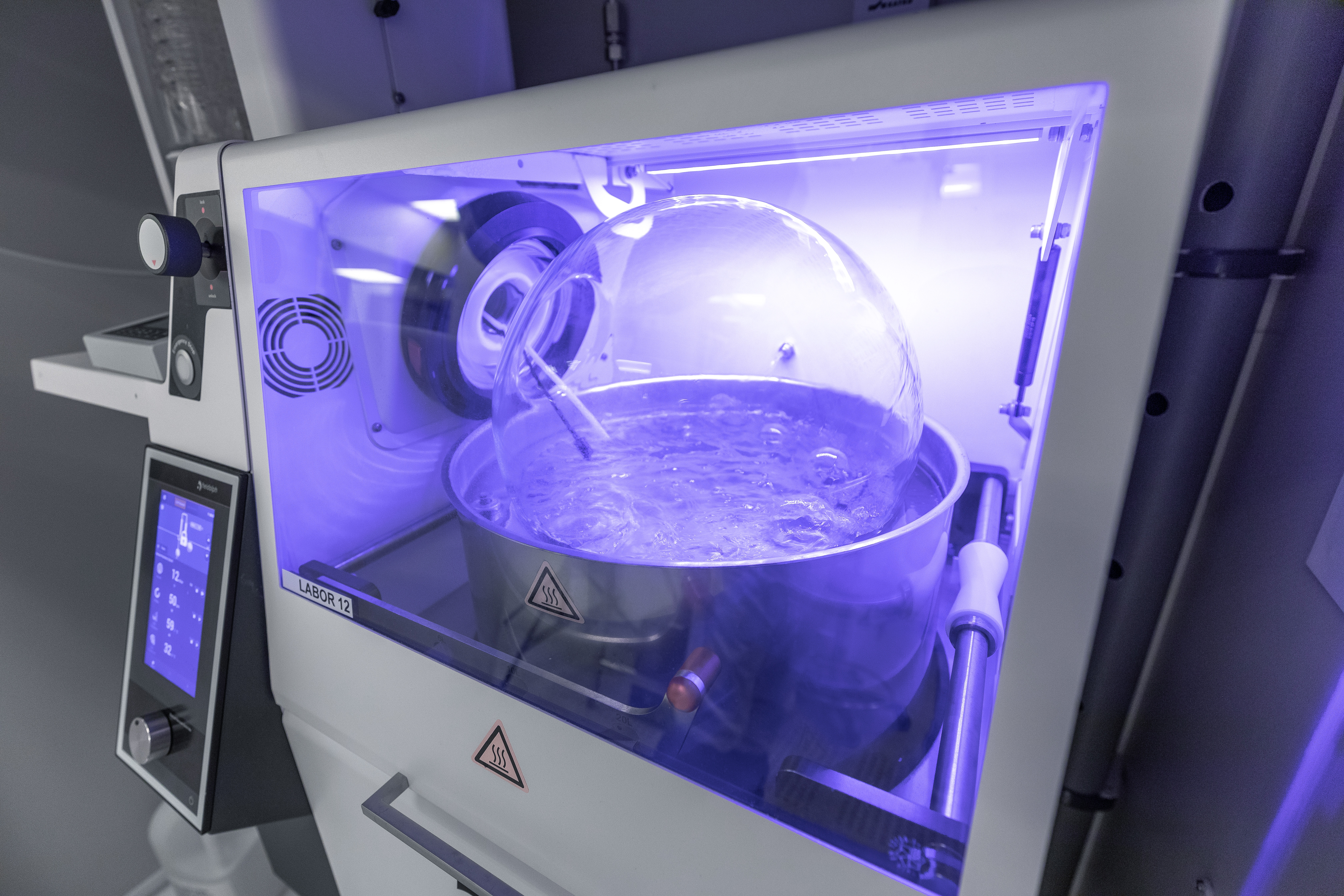

- Hei-VAP Industrial

- Hei-VOLUME

- Automatisation

- Distillation

- Solvants

- Évaporation

Customer: Pibond Oy (Finland)

Industry: Semiconductor and Pharmaceutical Applications

Application: Distillation of Ultra-High Purity Solvents

Background:

Pibond Oy specializes in the production of advanced spin-coated polymer products used in the semiconductor industry. These polymers require ultra-high purity (UHP) solvents, which are critical for achieving the performance and reliability standards expected in semiconductor and pharmaceutical applications. Impurities in solvents can negatively impact product quality, yield, and process consistency, making purification a key step in Pibond’s production workflow.

Challenge:

Commercially available ultra-high purity solvents are both cost-intensive and difficult to source in specific container sizes. To reduce dependency on external suppliers and to ensure a consistent supply of purified solvents, Pibond implemented an in-house purification process. Initially, this was done using manual or semi-automatic rotary evaporators. However, this method was labor-intensive and time-consuming, typically requiring up to three 8-hour shifts to produce a single batch of purified solvent for use in production.

Typical distillation volume: 200L

Typical distilled solvents:

PGMEA (propylene glycol methyl ether acetate)

PGEE (propylene glycol ethyl ether)

HMDSO (hexamethyldisiloxane)

Solution:

To increase efficiency and reduce operator workload, Pibond transitioned to using automated evaporator systems. These systems allow for continuous, unattended distillation of solvents. The process begins by filling the unpurified solvent directly from an external storage tank into the rotating flask, Hei-VOLUME Distimatic Pro then performs the distillation and refilling autonomously overnight, draining the purified solvent into another tank without the need for operator intervention.

Results and Benefits:

- Significant time savings: The automated process eliminates manual supervision, freeing up operator resources.

- Increased throughput: Solvent purification can run overnight with an uninterrupted distillation performance, enabling higher production capacity.

- Enhanced process reliability: Automation reduces the risk of human error and ensures consistent solvent quality.

- Improved logistics: The ability to purify in-house removes dependence on specific container formats and supply delays.

Conclusion:

By upgrading to an automated distillation system, Pibond Oy has streamlined its solvent purification process, supporting its commitment to ultra-high purity standards while improving overall production efficiency. This approach ensures a stable, cost-effective supply of solvents critical to the performance of its high-tech polymer solutions for semiconductor and pharmaceutical industries.

Produits d'occasion