Case Study

Sustainable Acetone recycling

March 2023

- Hei-VAP

- Evaporation

- Recycling

- Solvents

Sustainability is becoming an increasingly important consideration for different businesses, as the impact of their actions on the environment and society is becoming more apparent.

Besides businesses, universities also have an important role to play in promoting sustainability. As centers of research and learning, universities are uniquely positioned to advance the development and implementation of sustainable practices across a wide range of disciplines. This includes developing new technologies and processes that reduce environmental impact, as well as promoting sustainable practices in areas such as food systems, transportation, and energy use.

Furthermore, many universities have a tight budget, which brings another problem into display:, the rising costs of raw materials. Especially since the Covid 19 pandemic, solvents like acetone, ethanol, hexane, went up in price. Additionally, long delivery times made working in laboratories, who are dependent on solvents, a challenge.

Lee Hibbett, a Technical Manager of the Pharmacy School at the University in Nottingham, was facing those problems. A lot of students and other end users, are using acetone as a solvent to remove chemical residue from glassware before the actual cleaning process. Lee, discovered a few problems that go together with that practice:

· Rising costs of raw material (acetone)

· Large volumes of acetone used for cleaning purposes

· Disposal of acetone not environmentally friendly

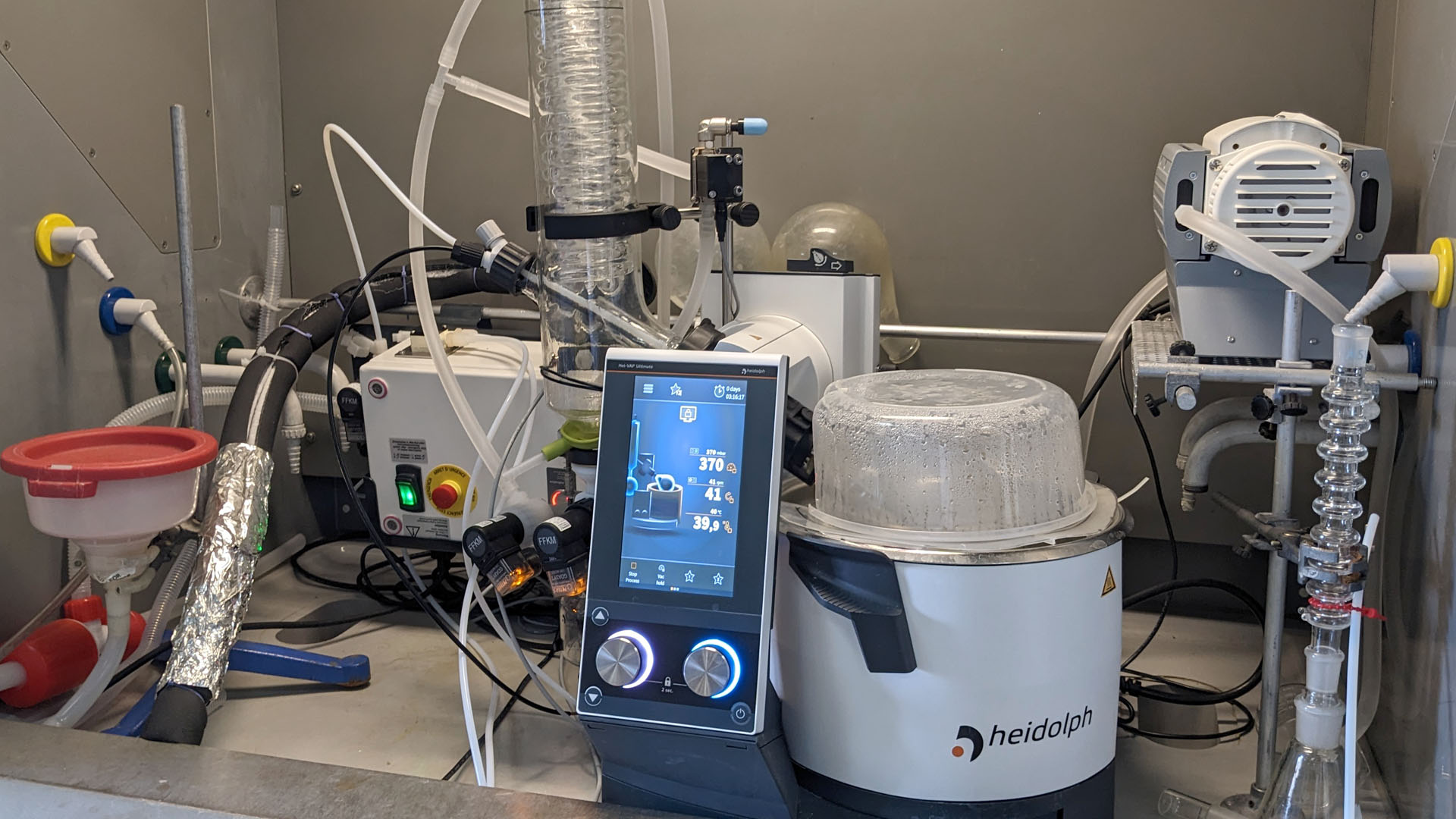

During his research for a solution, he discovered the Hei-VOLUME Distimatic, which is a system for automated solvent recovery and evaporation by Heidolph. The new system was installed quickly and since 2022, Hibbett and his team are steadily optimizing the right flow rate in order to get the best possible outcome. Right now, the team can recycle around 6 bottles of acetone per week, which equals to around 15 litres. Additionally, the cost for one bottle of clean, new acetone increased from £4.37 (2018) to £9.15 (2023). The fact, that Hibbett and his team were able to generate around 12 bottles of 2.5 litres clean recycled acetone in only 6 days of first testing that system, shows how financially beneficial the solution is for saving some budget already a couple of days after the installation Finally, to produce one tonne of acetone, around 2000 kg of CO2 are produced, whereas the recycling process reduces the amount of CO2 per tonne by 1.600 kg.

Therefore by implementing an automated module, the Hei-VOLUME Distimatic, Hibbett was able to tackle all upcoming problems surrounding rising costs of raw materials, long delivery times for chemicals and reducing the overall carbon footprint of the University.

Hibbett’s passion to implement sustainable approaches at work, not only got him the recognition at the University he works for, but also the Green Gown Award.

“Old ideas are not always the best – new ways of thinking can make a big difference.” – Lee Hibbett